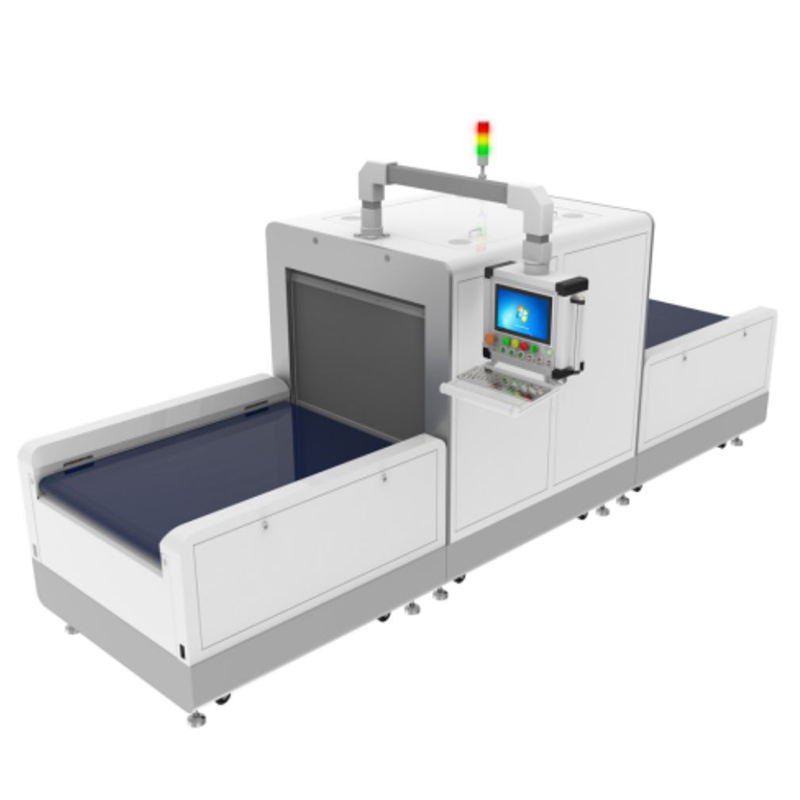

UHF RFID Tunnel Reader Model: ST-TR1

Introduction

ST-TR1 is an UHF RFID conveyor belt reader developed and designed by our company. With RFID technology as the core, combined with mechanical design, automation, multiple sensors, electromagnetic shielding and other methods, it solves the problems of high error rate and low efficiency of the traditional manual counting method during counting, incoming and outgoing goods review and other operations.

At the same time, when the channel machine is working, the list is generated on the display screen in real time, the data is verified, and the corresponding prompt and alarm are made to facilitate the management personnel to check, which greatly saves the labor cost and improves the work efficiency.

Industry application: it is mainly used in the identification of single grade items in the market, such as warehousing management and product inventory in clothing, leather goods, luggage, wine, electric power and other industries.

Features

1. Fast recognition speed, can identify more than 400 items within 3 seconds, and can generate a list on the display screen in real time;

2. Professional motion control and mechanical design technology can fully solve the problem of label missed reading;

3. Strict electromagnetic shielding design and radio frequency optimization can eliminate the harm of radio frequency radiation to the human body and ensure the accuracy of label reading;

4. The industrial computer software can control the functions of the whole machine and monitor the running status of all equipment. The external mechanical buttons are also equipped to facilitate the operator to control the working status of the equipment at any time;

5. The design of industrial plastic mesh port conveyor line fully solves the problem of offset maintenance of the conveyor line body;

6. There are overhaul doors on both sides of the passage to facilitate equipment maintenance;

7. Support the expansion of abnormal sorting modules to meet the needs of different users and support customers in the secondary development of application software;

8. The inventory efficiency has been increased by more than 100 times. The original manual inventory work requires 5-10 minutes, and the small conveyor belt inventory channel machine inventory only takes 3-5 seconds.

Technical Specification

| Main Specifications | |

| Model | ST-TR1 |

| Performance Specifications | |

| OS | Windows (optional for Android) |

| Industrial Personal Computer | I5, 4G+128(RK3399, 4G+16G) |

| Identification technology | RFID (UHF) |

| Reading Speed | 100pcs/s |

| Transmission speed | The default is 20m / min, and the maximum can be adjusted to 30m / min |

| Maximum load | 80kg |

| Reading speed | 6-10 box/min |

| Conveyor belt | 3 independent part |

| Door opening speed | 1.2s |

| UHF RFID | |

| Frequency range | 840MHz-960MHz |

| Protocol | ISO 18000-6C(EPC C1 G2) |

| RFID Chip | Impinj R2000 |

| RFID frequency mode | Fixed frequency / frequency hopping |

| Output power | 33dbm±1dBm |

| Tag reading quantity | ≥800 pcs |

| Read rate | 3~5s |

| Read mode | Static |

| Working mode | Cycle / trigger |

| Physical Specifications | |

| Material | 1.2mm thick carbon steel |

| Screen | 10” touch screen |

| Dimension | 1025mm*1554mm*3965mm( W*H*D) |

| Internal space | 785mm*592mm*1365mm( W*H*D) |

| Conveyor dimension | 1025mm*750mm*1300mm( W*H*D) |

| Carton dimension | 785mm*592mm*1065mm |

| Power supply | |

| Working power | Maximum power 250W, standby power 120W |

| working voltage | AC 220V |

| Operating environment | |

| Storage temperature | -20℃ — 60℃ |

| Working temperature | -20℃ — 60℃ |

Dimension